Cloud-based

SCADA

Access your plant anywhere

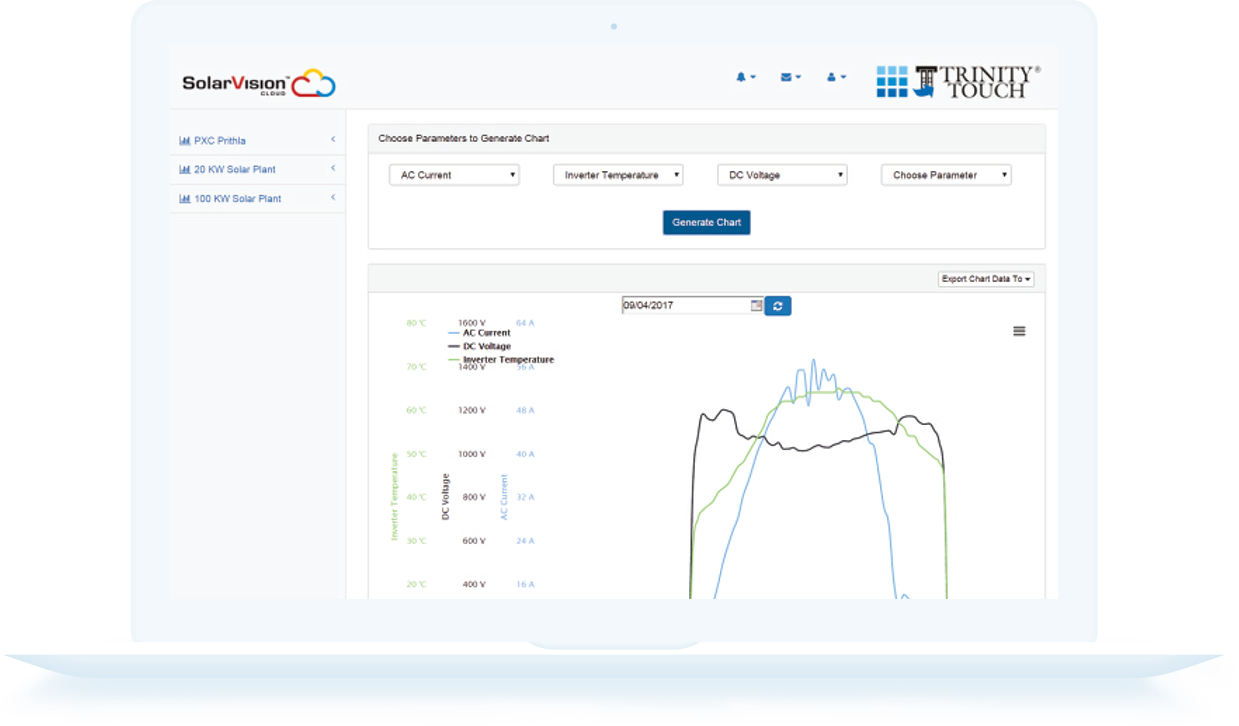

Introducing Trinity Touch’s SolarVision™ Cloud PV SCADA. It is essential to have a low cost reliable SCADA to ensure that maximum yield of a Solar PV plant. Once the sunlight is gone, there is no way to get it back, losing precious yield. SolarVision™ Cloud PV SCADA ensures that any problems in the field are notified to the plant operator as quickly as possible to utilise every ray of the sun. With many field instruments, the SolarVision™ Cloud SCADA guarantees seamless integration and communication with all field devices. SolarVision™ Cloud SCADA ensures remote monitoring from the internet cloud, especially designed for small ground mounted or rooftop Solar PV plants.

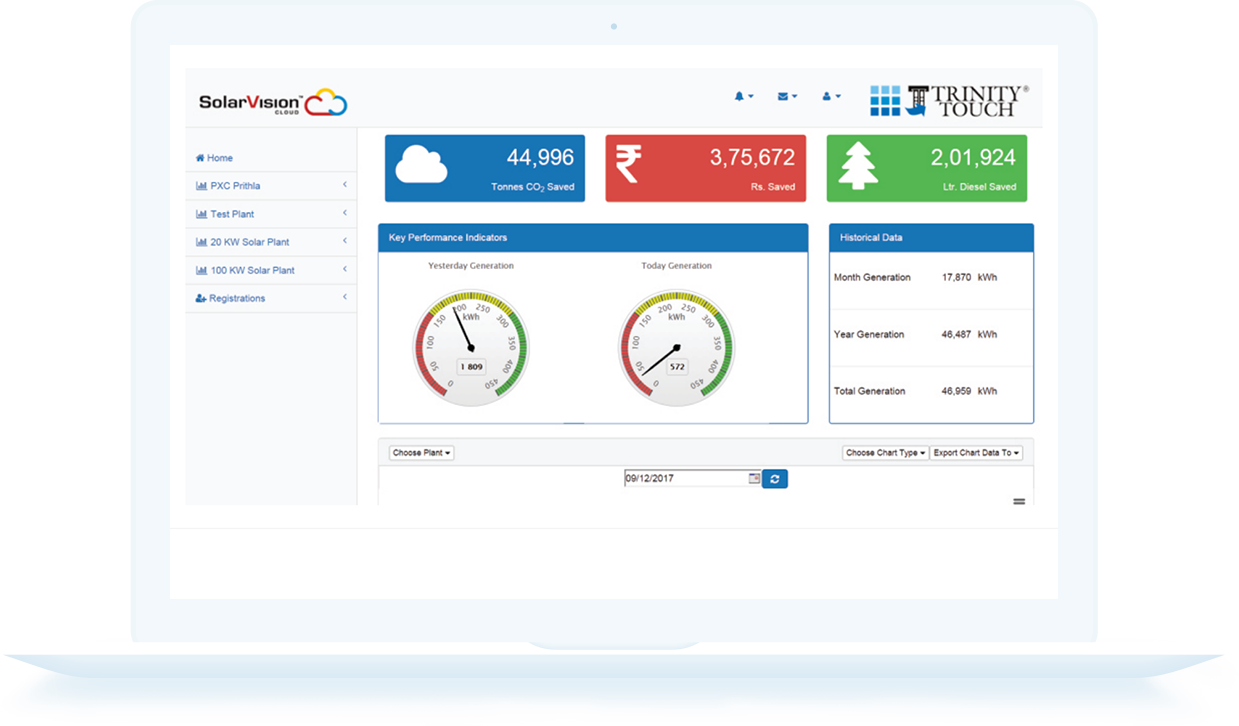

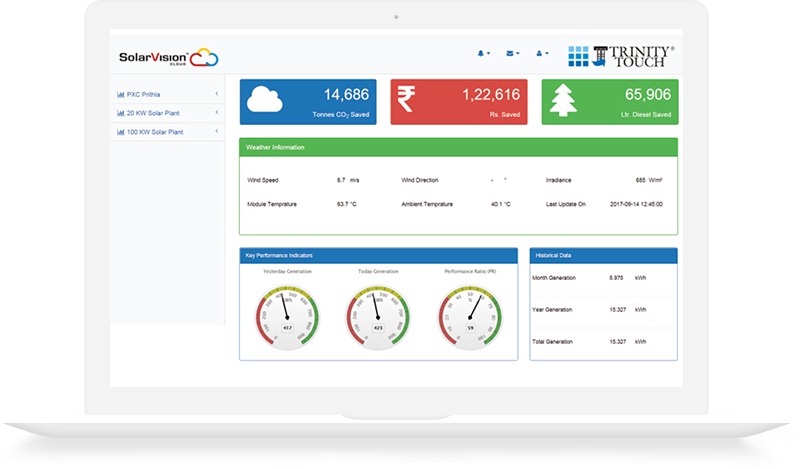

Maximum transparency & efficient operation thanks to innovate SolarVision™ Cloud plant visualization

SolarVision™ Cloud is an efficient and cost effective tool which continuously controls and monitors the solar plants, resulting in lower downtime increasing the Plant’s overall profitability. The data recorded from Analog sensor, Digital sensor, Inverters, Weather stations via Data logger is sent over Internet to our secured server & can be viewed online from anywhere in the world. SolarVision™ Cloud allows analyses in full detail depth and simple configuration of all alarm criteria for safely operating a PV system. The alarms are automatically triggered via email. Plant data is available for long term analysis over the service life of the PV Plant. Graphical interface of SolarVision™ Cloud satisfy the requirement of Investors/ Operator/ Service Engineer .

Highlights at a glance

- Cloud-based SCADA : you can access plant data, trends, and reports anywhere from internet.

- Modular Architecture. Analysis of Plant, Block, Inverter.

- Detailed monitoring & evaluation.

- Compatible with all RS485 / TCP/IP MODBUS inverters, weather stations.

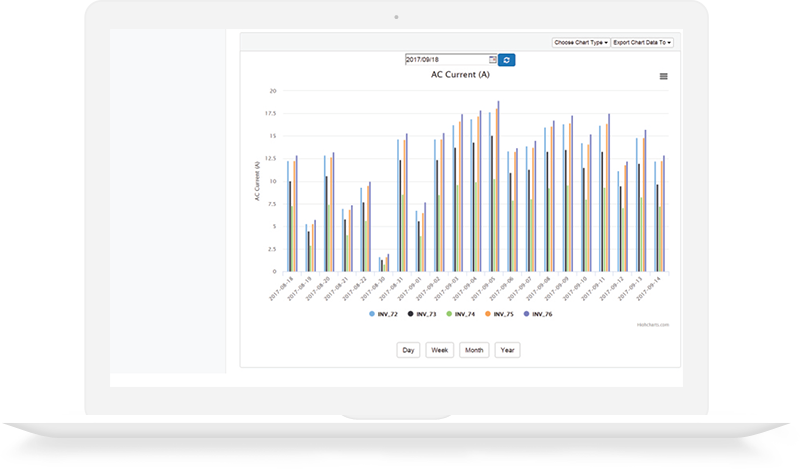

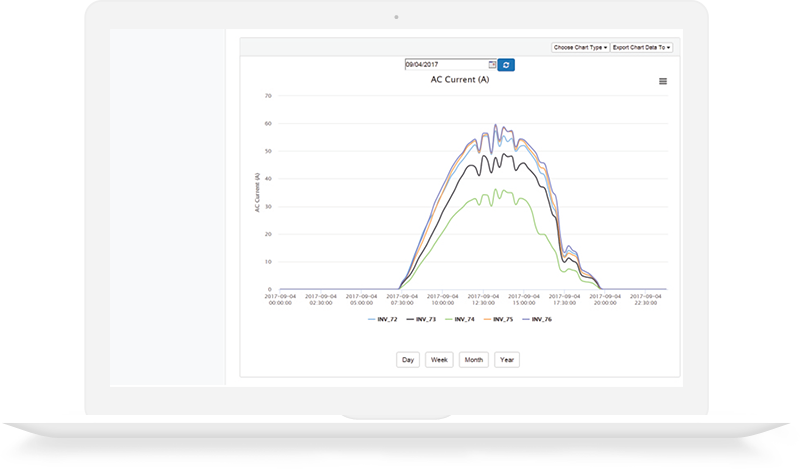

- Graphical Performance Analysis.

- Simple Alarm & Trend handling.

- Simple Report Generation.

- Easy Data BackUp.

- SMS & E-mail alerts

- System evaluation based on target/actual value comparison

- Energy vs PR comparison.

- Inverter status & alarms.

- Plant status & alarms.

Plant at a glance

SolarVision™ Cloud Visualizes entire plant, Weather Monitoring, Inverter & other important instruments including the associated detail information:

- The plant view shows the Weather Sensor’s data, Total Generation, Environment Information & Inverter & String Combiner Boxes Trends and Alarms for the Plant.

- Plant can be divided into various “Subsystems” for detailed monitoring.

- In the static screen important parameters are displayed e.g. Energy Generation, Historical energy generation data, Meteorological data.

- The detail Information of devices can be displayed by selecting appropriate graph.

SolarVision™ Cloud provides the plant analysis for important Meteorological data vs Plant performance.

- Energy Normalize

- AC Current Normalize

- DC Current Normalize

- Projected v/s Actual Generation

- PR v/s Generation

- Temperature v/s Generation

SolarVision™ Cloud analysis for inverter

- AC Power

- AC Current

- AC Voltage

- DC Power

- DC Current

- DC Voltage

- Frequency

- Inverter Temperature

- Inverter Frequency

- Inverter Status

Advanced optional features

- 1.Access protected by log in

- 2.Simulation (target/ actual value comparison)

- 3.Park administration

- 4.Email and SMS alerts

- 5.Managing user groups

- 6.Local Data Storage on PLC level in form of .csv up to 2 GB

- 7.Multiple plant generation monitoring capability for operating high number of plants

SolarVision™ Cloud analysis for plant:

Below parameters for a solar plant can be analysed on sinfle screen:

- 1.Total Generation

- 2.PR

- 3.Projected v/s Actual Generation

Hardware

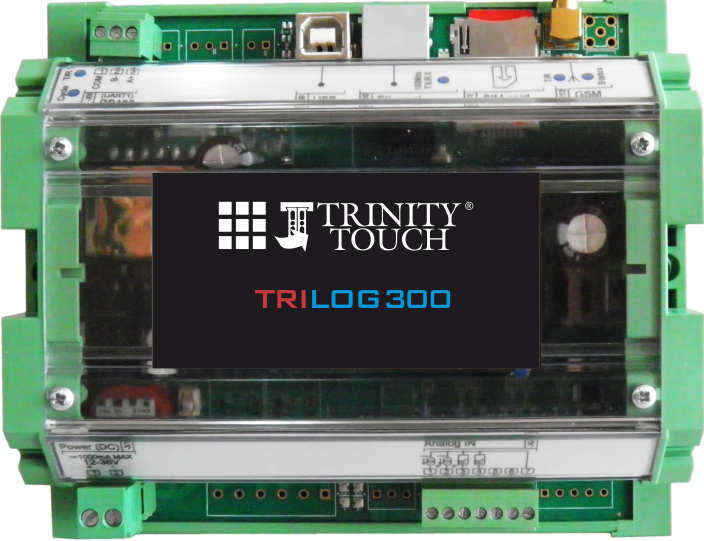

Datalogger With Reverse Power Protection

(Hybrid Power Management)

Data loggers designed specially for SolarVision Cloud are soughtafter specialists for optimised remote monitoring of photovoltaics systems. These provides complete monitoring of your photovoltaic system: all required operating parameters from Inveters, Multifunction Meters, Weather Sensors, DG Control, Grid Monitoring and Status & error messages of the connected devices. The data-logger records data every minute across various connected devices and logged the reading onto a storage card.

Data logger

| Controller Used | RS485 Input | Memory Card | Relay for Grid Failure detection | Digital Input | Digital Output | Analog Input | RTD Input | Reverse Power Protection | GSM GPRS | |

|---|---|---|---|---|---|---|---|---|---|---|

| Data Logger Type 1 | Phoenix Contact ILC 151 | 1 | 2GB | YES | 4 | 4 | _ | _ | _ | _ |

| Data Logger Type 2 | Phoenix Contact ILC 151 GSM/GPRS | 1 | 2GB | YES | 4 | 4 | _ | _ | _ | YES |

| Data Logger Type 3 | Phoenix Contact ILC 151 | 1 | 2GB | YES | 4 | 4 | _ | _ | YES | _ |

| Data Logger Type 4 | Phoenix Contact ILC 151 GSM/GPRS | 1 | 2GB | YES | 4 | 4 | _ | _ | YES | YES |

| Data Logger Type 5 | Phoenix Contact ILC 151 | 1 | 2GB | YES | 4 | 4 | 2 | 2 | _ | _ |

| Data Logger Type 6 | Phoenix Contact ILC 151 GSM/GPRS | 1 | 2GB | YES | 4 | 4 | 2 | 2 | _ | YES |

| Data Logger Type 8 | Phoenix Contact ILC 151 GSM/GPRS | 1 | 2GB | YES | 4 | 4 | 2 | 2 | YES | _ |

| Data Logger Type 8 | Phoenix Contact ILC 151 GSM/GPRS | 1 | 2GB | YES | 4 | 4 | 2 | 2 | YES | YES |

Datalogger For Monitoring

Datalogger for monitoring solar systems with records all relevant system data and also has Interfaces to communicate with Inverter, Measuring Devices and Weather Sensors. RTC, Real Time Clock synchronized through NTP protocol. RS485, USB, Ethernet, 3G (UMTS/HSPA+) communication. 4 analog inputs (current, resistance). 8GB microSD card included. FTP client able to send periodic data in csv file formatRemote configuration and updates through 3G(in 3G Model). Internal battery backup upto 2 hours. Galvanic isolation between power supply and communication interfaces.

Data logger

| Data logger | RS485 Input | Programming via USB input | Ethernet TCP/IP Input | Ethernet TCP/IP Output | Inbuilt 2G | Inbuilt 3G | On Board Memory | SD Card type | SD Card memory | RTD Input | Analog Input | Internal Battery | Nos of Inverters on TCP/IP | Nos of Inverters on RS485 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TRIlog100 2G | YES | YES | NO | NO | YES | NO | 8 MB | NO option to connect SD | NO | NO | NO | NO | 0 | 10 |

| TRIlog100 3G | YES | YES | NO | NO | NO | YES | 8 MB | NO option to connect SD | NO | NO | NO | NO | 0 | 10 |

| TRIlog200 | YES | YES | YES | YES | NO | NO | 8 MB | Micro SD Card | 8 GB | NO | NO | NO | 10 | 20 |

| TRIlog200 3G | YES | YES | YES | YES | NO | YES | 8 MB | Micro SD Card | 8 GB | NO | NO | NO | 10 | 20 |

| TRIlog+300 | YES | YES | YES | YES | NO | NO | 8 MB | Micro SD Card | 8 GB | 2 Nos | 2 Nos | YES | 10 | 20 |

| TRIlog+300 3G | YES | YES | YES | YES | NO | YES | 8 MB | Micro SD Card | 8 GB | 2 Nos | 2 Nos | YES | 10 | 20 |

Irradiation Sensor

Si-RS485TC-2T-v-MB

- Integrated Sensor with MODBUS RS485 Output

- Silicon Irradiance Sensor

- Cell Temperature Sensor

- Wind Speed Sensor

- Ambient Temperature Sensor

| Article No. | Description |

|---|---|

| 12413029 | Si-RS485TC-2T-v-MB I+M+External A & Wind |

| 12413031 | Vwind-Si connect to Si-RS485TC-2T-v-MB |

| 12413034 | Tamb-Si connect to Si-RS485TC-2T-v-MB |

Irradiation Sensor RT1

- Designed for rooftop PV installations

- Fits to a corner of any solar panel

- Irradiance and back-panel (module) temperature measurement

- Recalibration not needed for 5 years

| Article No. | Description |

|---|---|

| 12412046 | Rt1 Roof top Irradiance with Module Temp |

Compact Weather Station

WS-502 (With Horizontal Silicon Irradiance Sensor), WS-504 (With Tiltable Silicon Irradiance Sensor)

- Silicon Irradiance Sensor

- Ambient Temperature

- Relative Humidity

- Air Pressure

- Wind Direction

- Wind Speed

- Module Temperature

| Article No. | Description |

|---|---|

| 13500003 | WS-502 UMB 8375.U10) |

| 13500037 | WS-504 UMB 8375.U12 |