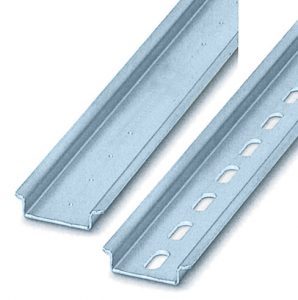

DIN ‘G’ Rail 32/15

TDR3 (Third Generation Passivation)This series of DIN Rail is for industrial application conforming to the European standard EN 60715 with THIRD generation passivation of Cr+ Iridescent color, higher thickness film 300nm~400nm, SST stability of 240Hrs. It has an advantage of being fluoride free, organic acid free and has a low metal concentration and improved corrosion resistance. TDR2 (Second Generation Passivation)This series of DIN Rail has SECOND generation passivation of Cr , silver chromated, higher film thickness of 200nm~400nm SST stability upto 240 Hrs, and improved corrosion resistance as compared to the FIRST generation passivation.

MOREDIN Rail 15/5.5

TDR3 (Third Generation Passivation)This series of DIN Rail is for industrial application conforming to the European standard EN 60715 with THIRD generation passivation of Cr+ Iridescent color, higher thickness film 300nm~400nm, SST stability of 240Hrs. It has an advantage of being fluoride free, organic acid free and has a low metal concentration and improved corrosion resistance. TDR2 (Second Generation Passivation)This series of DIN Rail has SECOND generation passivation of Cr , silver chromated, higher film thickness of 200nm~400nm SST stability upto 240 Hrs, and improved corrosion resistance as compared to the FIRST generation passivation.

MOREDIN Rail 35/7.5

TDR3 (Third Generation Passivation)This series of DIN Rail is for industrial application conforming to the European standard EN 60715 with THIRD generation passivation of Cr+ Iridescent color, higher thickness film 300nm~400nm, SST stability of 240Hrs. It has an advantage of being fluoride free, organic acid free and has a low metal concentration and improved corrosion resistance. TDR2 (Second Generation Passivation)This series of DIN Rail has SECOND generation passivation of Cr , silver chromated, higher film thickness of 200nm~400nm SST stability upto 240 Hrs, and improved corrosion resistance as compared to the FIRST generation passivation.

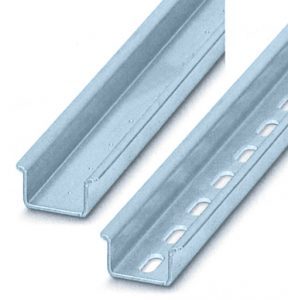

MOREDIN Rail 35/15

TDR3 (Third Generation Passivation)This series of DIN Rail is for industrial application conforming to the European standard EN 60715 with THIRD generation passivation of Cr+ Iridescent color, higher thickness film 300nm~400nm, SST stability of 240Hrs. It has an advantage of being fluoride free, organic acid free and has a low metal concentration and improved corrosion resistance. TDR2 (Second Generation Passivation)This series of DIN Rail has SECOND generation passivation of Cr , silver chromated, higher film thickness of 200nm~400nm SST stability upto 240 Hrs, and improved corrosion resistance as compared to the FIRST generation passivation.

MOREUniversal DIN Rail Cutter

UNIVERSAL DIN CUTTER Bench top Profile Cutter with five built in dies for manual cutting of common DIN rails to custom length.Tool is intended for use where multiple DIN rails are to be cut without changing the die.

MORE